![]()

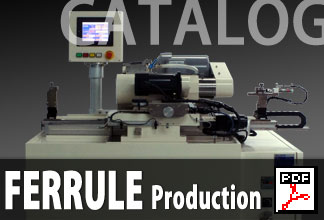

Concentricity Processing Machine | TM-3

It is a succeeding model of TS-2A. By the large change of design, it succeeded in a miniaturization, improvement in maintenance nature, and shortening of machining time, and also realized improvement in concentricity.

A wire-centerless system is adopted and a ferrule outside diameter is processed with high precision on an inside diameter standard (supply of a work is a semi autotype performed manually).

50 processings are possible if it is SC ferrule in once. (LC ferrule 82 pieces)

It can respond to SC and LC by adjustment of exchange of a braid, a grinding stone, and a adjusting wheel.

In addition, it corresponds also to a special size.

Feature

- 200 processings/hour were attained by SC type (when it is 50um processing).

- It is an average of 90% or more (it is a track record value and is not a guaranteed performance) at the time of 1.0 or less um of the concentricity, and mass production.

- By the addition of the stepping motor, the maintenance of the adjusting wheel became easy.

- The miniaturization was attained and it succeeded in the cost cut.

- It is preparing various options, in order to meet a user's request.

Technical Specification

| Machine size (W×D×H) | 1400mm x 1100mm x 1400mm |

| Machine weight | 650kg |

| Grinding stone order movement | 35mm |

| Adjusting roll order movement | 40mm |

| Traverse right-and-left movement | 600mm |

| Grinding stone spindle oil supply | Oil mist |

| Adjusting roll spindle oil supply | Oil mist |

| Coolant oil capacity | 50L |

Option | Consumables

| Option | PCD braid |

| Various stroke change | |

| Special diamond wheel | |

| Consumables | Piano wire |

| Coolant oil | |

| Filter | |

| Spindle oil | |

| Thin pipe | |

| Equipment consumables | Diamond wheel |

| Adjusting roll | |

| Carbide braid | |

| GC grindstone for dress | |

| Diamond dresser |

Line up of Ferrule Processing Machine