![]()

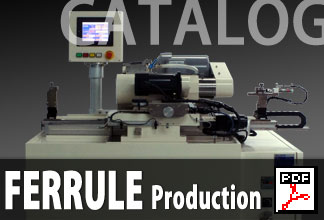

I/D Processing Machine(One by one auto Type) | IRM-A2 NEW !!

It is the inside diameter processing machine which automated the conventional one by one processing machine.

It is hard to be subject to the influence of a material.

So an advantage, like roundness and concentricity are good can be employed efficiently.

Moreover, reduction of the personnel expenses by automation, rise of processing efficiency, and quality stability are also realized.

Feature

- Problems, such as poor roundness resulting from material quality, can be reduced sharply.

- In SC type case, 400 pcs/h processing track record (work set time is included).

- Reduction of the personnel expenses by automation is possible (2-3 sets of one-person managements are possible).

- A metal fixed machine, wire rolling up, etc. are unnecessary, and incidental facilities decrease.

Technical Specification

| Processing ability | 9 - 15 pcs/sec |

| Processing way | one by one |

| Processing | Automatic |

| Supply | Munual (use jig for supply) |

| Control | Touch panel |

| Operation | PLC |

Option | Consumables

| Consumables | Piano wire |

| Diamond powder | |

| Oil for slurries | |

| Equipment consumables | Collet chuck |

Wire Etching Machine for IRM Series | TBW-IRM (Incidental Equipment)

It is the equipment which manufactures the taper wire used for one by one type automatic inside diameter processing machine "IRM-A2."

| Machine size (W×D×H) | 590mm x 460mm x 1620mm |

| Machine weight | 50kg |

| Operation | PLC |

| Consumables | Etching solution |

| Neutralizing solution | |

| Felt |

Line up of Ferrule Processing Machine