![]()

Inside Diameter Processing Machine(Auto Type) | TLA-5

It is the new style automatic inside diameter processing machine which applied the know-how acquired with the manual inside diameter processing machine, repeated improvement and was completed.

By eliminating the indispensable metal fixation for automatic inside diameter processing until now, it succeeded in simplification of a large process, and shortening of time.

A diamond slurry is made to adhere to a taper wire, and inside diameter processing is performed by moving an inside diameter, detecting the load concerning a wire.

Supply of a work is performed manually.

It can respond to various processing sizes by the taper wire and setup.

Feature

- About 350 processings/hour are possible by SC type (it changes with material inside diameters).

- Since an inside diameter size is stabilized, it excels in mass production nature.

- A fine condition setup was attained by soft upgrade.

- The miniaturization was attained and it succeeded in the cost cut.

Technical Specification

| Machine size (W×D×H) | 1000mm x 480mm x 873mm |

| Machine weight | 140kg |

| Operation | Touch panel |

Option | Consumables

| Option | Special work set jig |

| Consumables | Piano wire |

| Diamond powder | |

| Oil for slurries | |

| Equipment consumables | Work set jig |

| Rubber for jig |

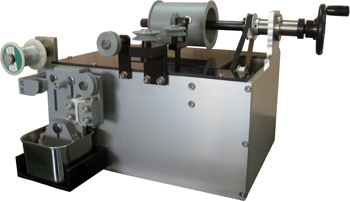

Wire Winding Machine for TLA Series | TBW-M (Incidental Equipment)

It is a pretreatment facility for manufacturing the taper wire used for an automatic inside diameter processing machine "TL-A."

A wire and a bobbin are installed, and it rolls round in a bobbin at a fixed interval, degreasing a wire by turning a handle at a fixed speed.

| Machine size (W×D×H) | 500mm x 365mm x 330mm |

| Machine weight | 25kg |

| Drive system | Manual |

| Consumables | Solvent degreasing |

| Felt |

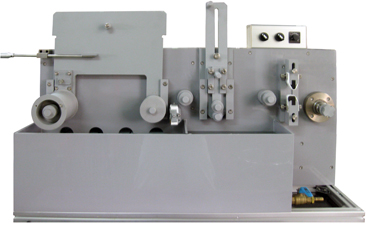

Wire Etching Machine for TLA Series | TBW-A (Incidental Equipment)

It is the equipment which manufactures the taper wire used for an automatic inside diameter processing machine "TL-A."

The wire wound around the bobbin with the wire winding machine "TWM-M" is sunk into an etching layer, and it rolls round in the bobbin for TL-A processing, carrying out neutralization and degreasing.

Operation is automatic rolling up and it controls it by a changeover switch.

By an adjustment valve, speed change is possible, and it adjusts wire size with speed.

| Machine size (W×D×H) | 1130mm x 500mm x 500mm |

| Machine weight | 50kg |

| Drive system | Toggle switch ON/OFF |

| Consumables | Etching solution |

| Neutralizing solution | |

| Felt |

Line up of Ferrule Processing Machine