|

Ferrule Processing Machines |

|

|

|

|

|

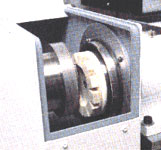

Horizontal Grinding Machine

SGM-6301 |

|

|

|

|

|

|

For finishing the surface on both sides of the Ferrules. For finishing the surface on both sides of the Ferrules. |

Workpiece is put by manually controlled.

Workpiece is put on Triangle Jig and Triangle Jig is installed working

table by Electro Magnetic Chuck.

300 pcs/1cycle for

SC Ferrule and 600 pcs/1cycle for LC Ferrule. |

|

|

|

|

|

|

|

|

| Specification |

Maximum Diameter of the Works |

150mm |

| Traverse-stroke of the Work spindle |

50mm |

| Stroke of the Wheel spindle |

25mm |

| Maximum Diameter of the Wheel |

200mm |

| Work spindle R.P.M. |

2000R.P.M |

| Wheel spindle R.P.M. |

410R.P.M |

| Work spindle Motor |

750W |

| Wheel spindle Motor |

200W |

| Work spindle feed motor |

60mm |

| Coolant Pump |

25W |

| Capacity of the Coolant tank |

50L |

| Diameter of the Work-chuck |

125mm |

| Digital Counter |

attached zero-set |

| Total Electric Power |

1035W |

| Size and Weight |

Size |

1,150mm×500×1,230mm |

| Weight |

450Kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Diamond wheel |

|

SS-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Triangle Jig |

|

|

|

|

|

|

|

|

|

|

|

|

|

|